Equipment and Modeling Capabilities

Cai Research Lab (top)

- Newly-built 100 sq meter (1080 sq ft) modern lab space.

- Two 6 feet Premier fume hood and two sinks.

- Glass door/window from both sides of the lab.

Student Office and Lounge Areas (bottom)

- Open-space student working and louge area, right next to (outside of) the research lab with gorgenous view of the VT blacksburg campus.

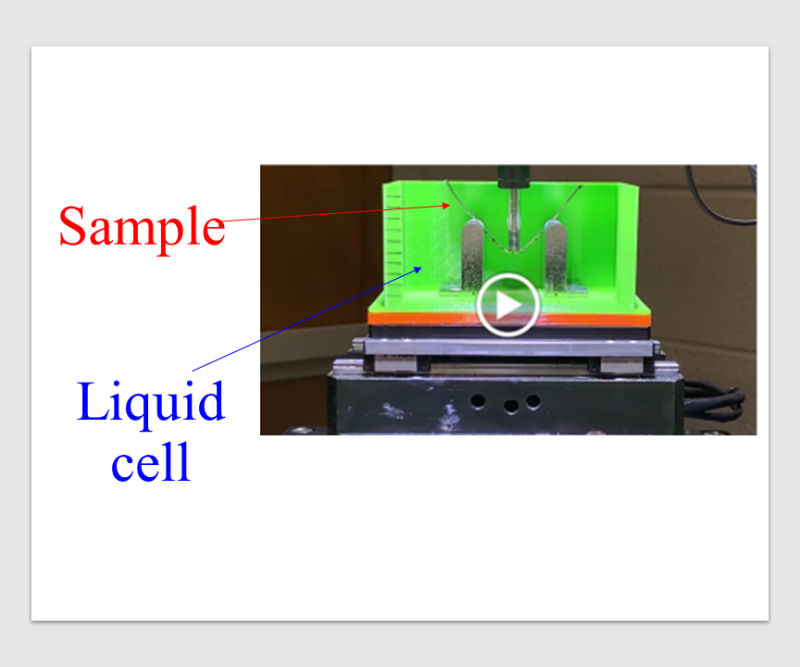

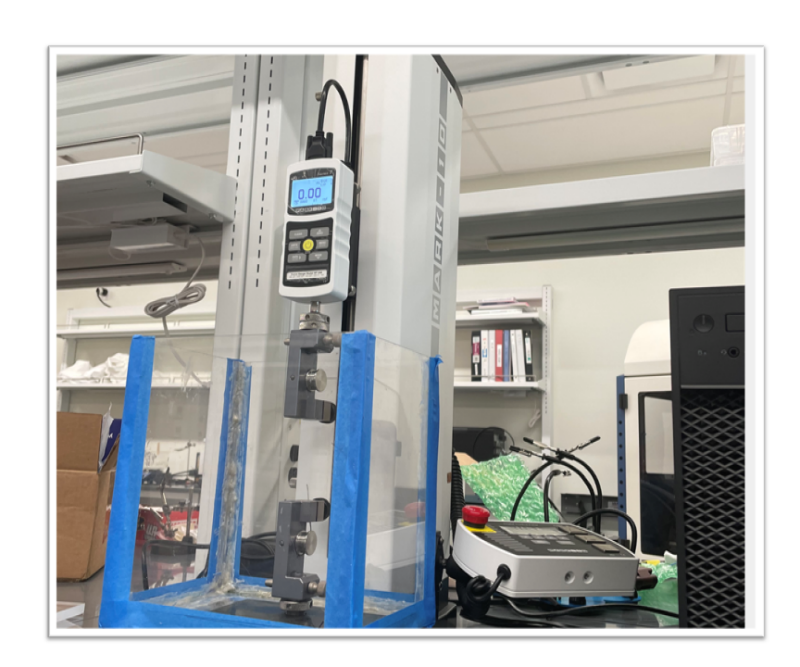

3-Point Bending SCC Tester in Liquid Cell

- In-situ force-displacement, and electrochemical current/potential measurements.

- 2D strain field, crack initiation and propagation is measured in-situ using Digital Image Correlation (DIC) system.

- Suitable for testing fibers, wires, plates, bars, etc. in liquid solution.

Q-Fog SSP-600 cyclic corrosion test chamber

- Cyclic corrosion testing provides the best possible laboratory simulation of natural atmospheric corrosion, performance is similar to outdoors in resulting structure, morphology, and relative corrosion rates.

- Q-FOG cyclic corrosion chambers can run salt spray, Prohesion, and most cyclic automotive tests with temperature control up to 70 oC.

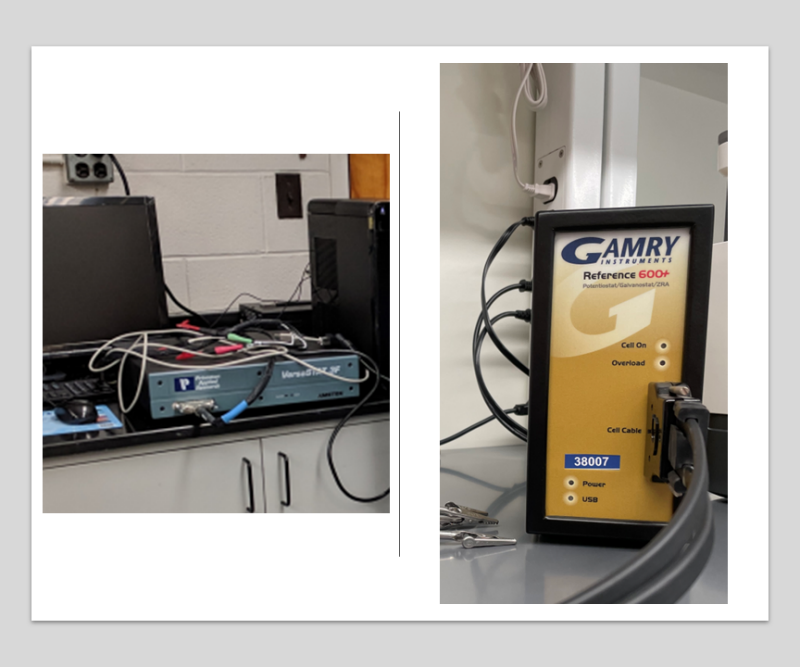

Potentiostat/Galvanostat/Zero Resistance Ammeter

- Corrosion testing and electrochemical measurement. Electrochemical Noise Experiment, Electrochemical Frequency Modulation, Pulse Voltammetry, Electrochemical Impedance, and Electrochemical Signal Analyzer.

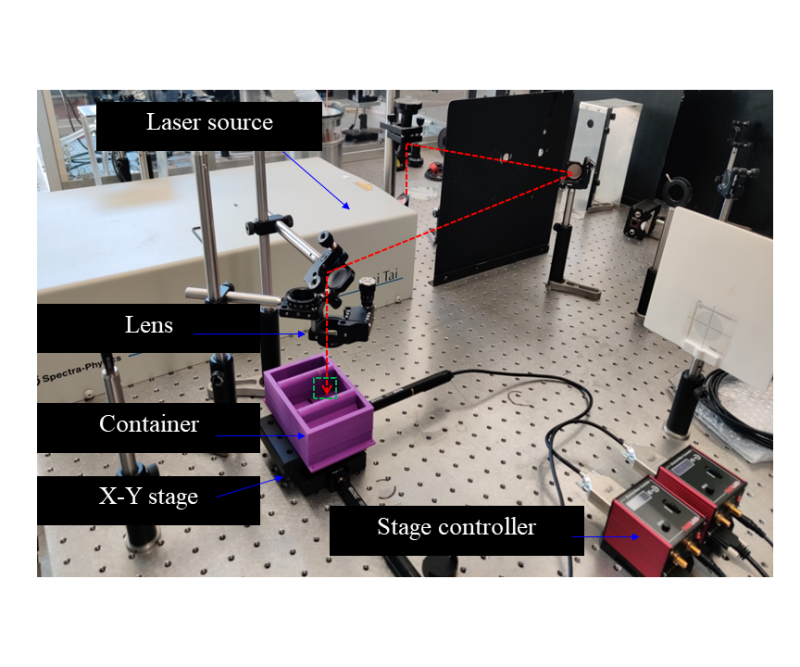

fs-LSP system (in collaboration w/ Prof. Vinh)

- Ultra-fast laser shock peening system.

- Suitable for enhancing surface proeperties such as wear, corrosion, stress-corrosion, and fatigue resistance.

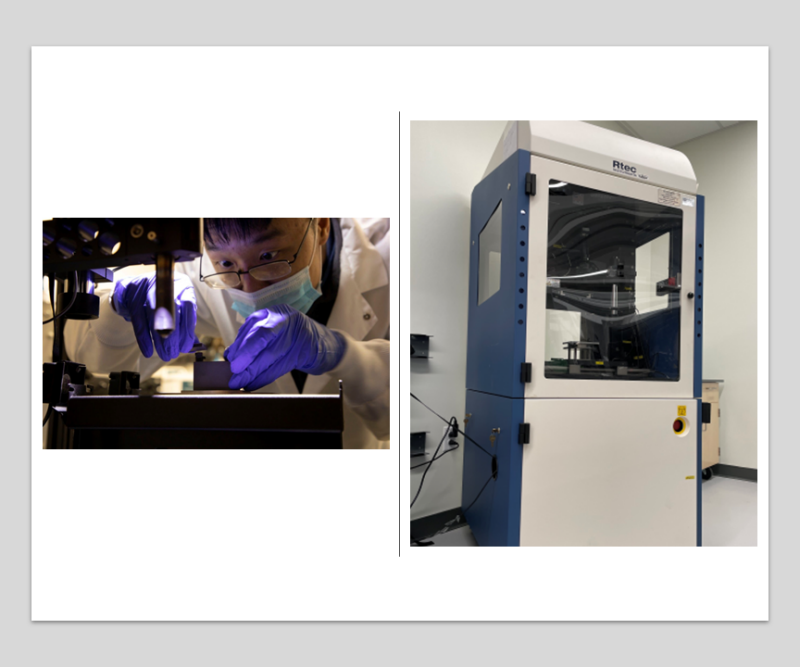

Rtec MFT‐5000 multifunctional tribometer

- Micro-Macro wear and scratch test: The standard test to determine wear rate and friction coefficients of thin films, coatings, 2D and bulk materials. 2D force senor (mN-N) and z-displacement sensor (nm-micron), 10x camera, ball and pin tip holder.

- Tribocorrosion Test: Determines tribocorrosion, erosion corrosion of materials at room temperature – 80 oC in liquid cell w/ in-situ corrosion current/potential monitoring. Testing standard: ASTM G119.

- High-Temp Tribology Test: Linear oscillating test, room temp – 1000 oC in air. Testing standard: ASTM D5706, D5707, D6425, D7217, D7420, D7594,D7421,DIN51834 /2/3/4/5/6/7/8/9.

Tensile and Stress Corrosion Cracking (SCC) Testing

- In-situ stress-strain, and electrochemical current/potential measurements. Load Capacity: 300 lbf [1.5 kN].

- 2D strain field, crack initiation and propagation is measured in-situ using Digital Image Correlation (DIC) system.

- Suitable for tensile and compact tension specimens.

Vacuum Induction Melting System

- Melting temperature up to ~ 2000oC.

- Output power: 2 - 25 KW.

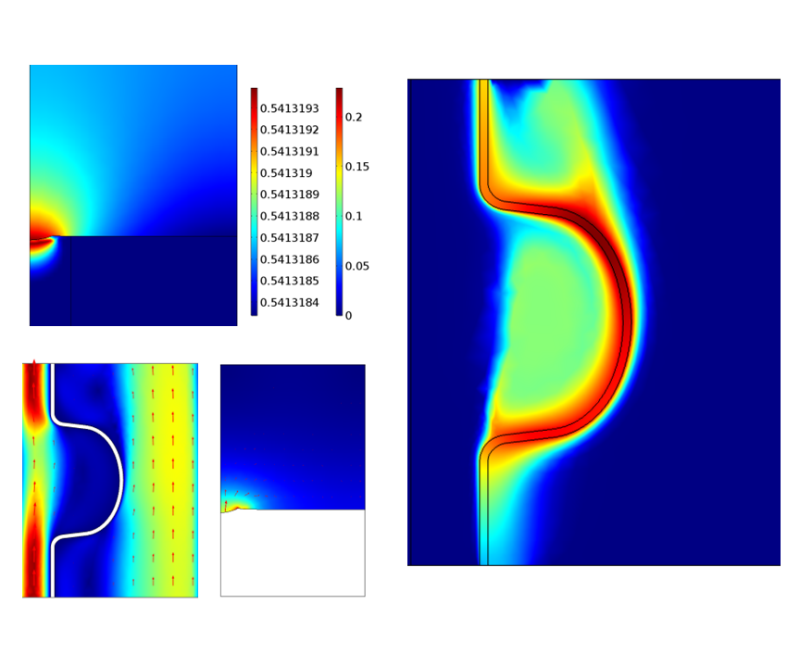

Multiphysics FEA Modeling

- Finite element based multiphysics modeling (stress, corrosion, wear, thermal, fluid etc.)

- Tribocorrosion, stressed corrosion, complex electrochemical modeling with the coupling of thermal, fluid dynamics, solid mechanics, and electrochemical kinetics.

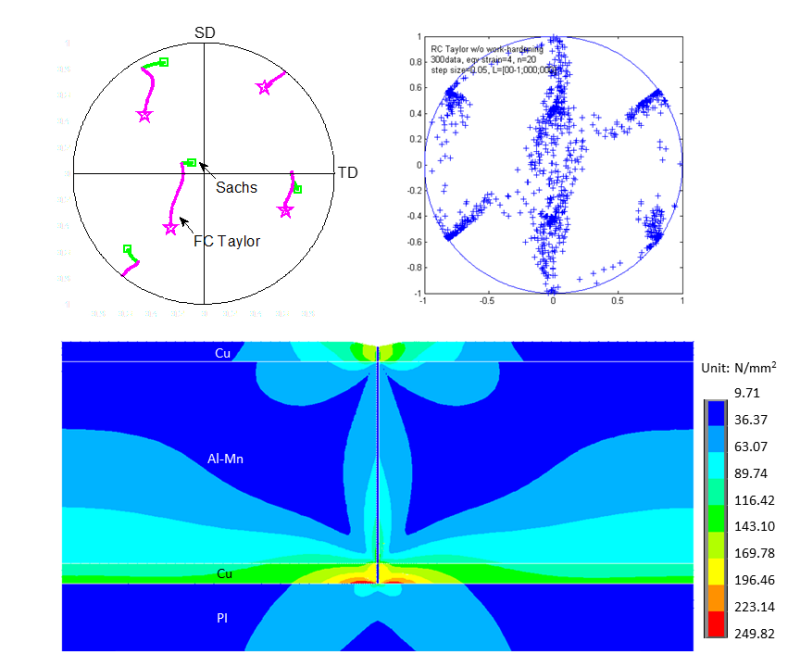

Crystal Plasticity and Fracture Modeling

- Crystal plasticity modeling of texture evolution during plastic deformation.

- Fracture mechanics modeling via cohesive zone models.